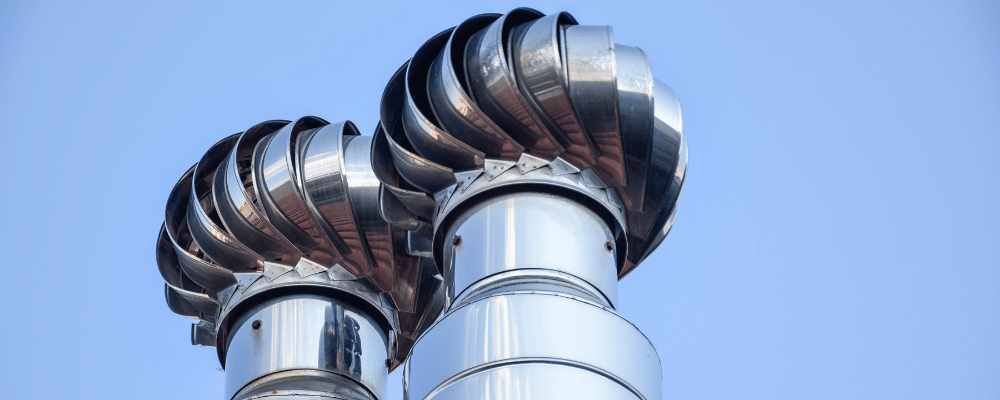

Chimney cowls

ROTATIONAL CHIMNEY POT SYSTEM - SYSTEM KOMINUS®KN CHARACTERISTICS OF KN SYSTEM

KN system is a system of rotational chimney pots made of stainless steel and copper. We distinguish chimney pots applied in a flue- Rotomax and applied in ventilation systems- Turbomax.

WHY POTS?

The basic function of both types of chimney pots is to ensure the proper chimney draught. This is the most important aspect that is responsible for proper chimney work. Rotomax cowls are used in flues in exhaust systems for appliances burning gas and fuel oil. Thanks to the proper shape and use of modern bearings they set up in front of blowing wind and protect the chimney duct. Blowing wind can lead to chimney draught whirling and in effect to reverse draught. In ventilation ducts cowls have to increase the chimney draught what ensures the proper air circulation inside the building. Turmomax, which is " rotation ball", thanks to its proper shape perfectly uses the power of the wind by rotation. It causes force with the turn opposite to the wind direction and protects the chimney. We can proof it in a very easy way. You can You can feel the air flowing in direction of our hand. It builds a barrier between rotating cowl and surrounding environment.

TIPS FOR THE BUYING, HOW TO PICK THE CORRECT CHIMNEY COWL?

The basic criteria of picking the chimney cowl is the mentioned above division between flues and ventilation ducts. It should be remembered that under no circumstances chimney cowls for flues should be used for ventilation ducts and vice versa, because they won’t be able to fulfil their basic functions. After defining which cowl are we to pick, the next thing to be taken into consideration is the type of base. For both chimney cowls two types of base are available – square base and tubular base. Chimney cowls with a square base have holes in corners which makes it easy to fasten them to the chimney Such fastening is durable and it protects the cowl from breaking off in a case of a strong wind. Chimney cowls with a tubular base are used for chimney with circular cross section flues and ventilation ducts. In such case, a base for fastening is not required. Fastening is much simpler Just put the chimney cowl pipe into the flue or duct and it’s ready – without any additional complication and fixing. After picking the correct chimney cowl and it’s base we need to choose the diameter. It should be remembered that choosing the correct diameter ensures that the chimney cowl will work well. In the case when the diameter is to small in relation to the existing flue or duct, turbulences can appear or the square base cowl will not cling to the liner and will just drop into the flue or duct. The existing flue or ducts should be measured beforehand. The diameter should be chosen to coincide with the existing flue or duct as much as possible In the case of circular cross section flues and ducts there is no problem, because knowing its diameter we can choose the chimney cowl just slightly smaller, which will allows us to slip the cowl into the flue or duct. It’s a bit more difficult in the case of square cross section flues and ducts, because determining an optimal diameter, which will coincide the most with the square, is required. Due to the fact that the chimney cowl is fastened to the flue or duct and not slipped into it (as it has the place with the square cross section flues and ducts), the diameter should coincide as much as possible with the existing chimney flue or duct. When all the information mentioned above is gathered, the last but also the most pleasant choice is to be made – which chimney cowl model we want to pick. In this regard we can rely on our tastes and pick the model we like the most. People who prefer simplicity often pick the traditional models. People who prefer sophisticated shapes will often pick the models with sophisticated shapes, whereas people who look into future often pick models with the newest motives. After choosing the model, we just need to buy the chimney cowl and fasten it to the chimney. In effect we can be happy that the chimney choose not only fulfills its functions, but also looks nice and people will surely notice it, when walking next to our house.

CHIMNEY COWL’S PROPER MAINTENANCE AS THE SOURCE OF LONG-TERM VIABILTY

Chimney cowls also need maintenance. In the case of Rotomax rotary type, which functioning is based on the bearing, responsible for the rotation of the cowl, lubrication of bearings with graphite grease is necessary. This will protect the parts most exposed to the friction force and will protect against the ‘creaking effect’, cause by not lubricated bearings.

WHAT ABOUT CHIMNEY’S CLEANING?

Chimney cowls are made is such way that they don’t cause problems while cleaning the chimney. Rotary cowl can be easily taken off for cleaning the flue or duct. On the side of the cowl there’s a small knob, which, when turned, allows to take the topmost part off. It is important to check if the knob is at its starting position, horizontal, after the topmost part had been put on the cowl. Leaving it in a vertical position may lead to blocking of the cowl’s movement

WHAT IS GUARANTED BY KN SYSTEM

- high quality

-The option of choosing the proper diameter, based on the cross-sectional dimension of the flue or duct

- usage comfort

- Aesthetic design, adapted to modern trends in construction

All chimney systems we manufacture meet high quality requirements, which are confirmed by the obtained certificates. The issuer of the certificates is MPA NRW - MATERIALPRÜFUNGSAMT NORDHEIN-WESTFALEN, a recognized independent institute for testing product compliance with standards. Due to the laboratory capabilities, experience and staff of specialists, it is the most recognized institution controlling compliance with standards.